- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

12F

Elepedol

24V / 36V / 48 V

500W / 750W / 1000W / 1500W

| Availability: | |

|---|---|

| Quantity: | |

SPECIFICATION

| Product name | 12 mosfet ebike controller |

| Model | 48V 30A 35A-AW/Normal |

| Rated Voltage | DC24-72V |

| Rated current | 20A |

| Maximum current | 40A |

| Rated power | 480W-1440W |

| Maximum power | 2880W |

| Static power comsuption | <50mA |

| Under-voltage protection | it can be set according to customer requirements |

| Driving mode | Sinewave or Square wave for option |

| Waterproof | Basic protection of water washout IP64 |

| Electromagnetic compatibility(EMC) | Outgoing lines can be added with the jacketed ring for interference protection |

| Lights drive | Optional headlight control and instrument headlight indicator |

| Housing color | aluminum natural or black |

| Product certification | CE certification |

Usually, 12 mosfet controller is used to fit 750W 1000W 1500W standard electric bike hub motor.

The ebike controllers we provide use imitate torque control mode to help achieve a smooth start-up of the vehicle, the power-assist drive will be smooth and natural.

Electric power assist is with fast response and always consistent with the rider's pedal action to achieve the effect of the torque boost.

With multiple protection features such as stalled, over-current, over-temperature, over-voltage, under-voltage, speed, lack of phase and so on to protect the safety of vehicle electronic control systems and traffic.

There are motors with or without Hall, which fit all kinds of high and low speed motors.

There are two options of simulated sine wave or square wave controller.

NC model

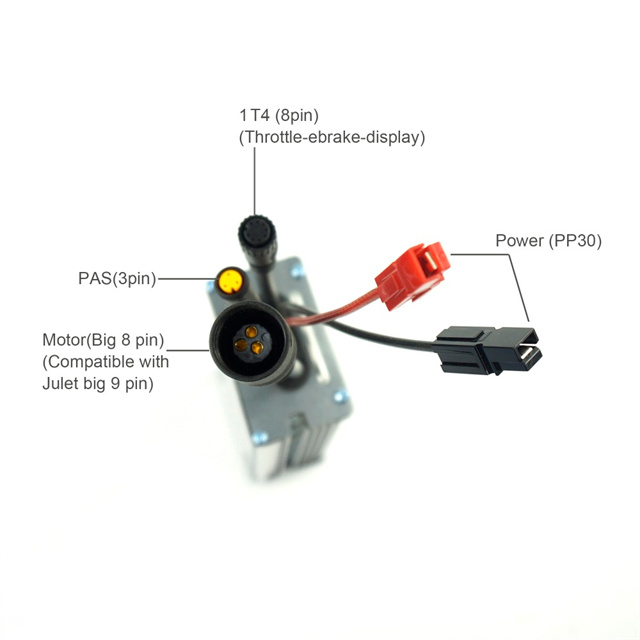

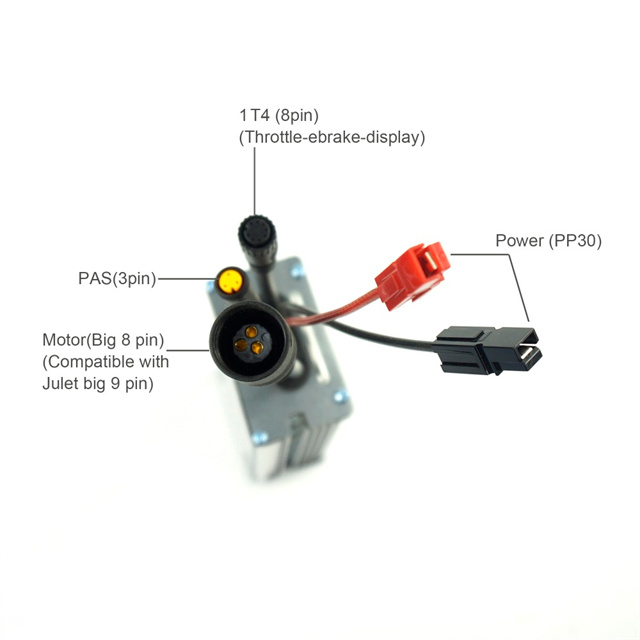

12 mosfet ebike controller with normal SM connectors

(Motor connector is Julet 8 pin waterproof connector)

12 mosfet ebike controller with Julet waterproof connectors

Size information for the 12 mosfet ebike controller aluminum case:

Someone will have questions, why the AW model controller have fewer cables in the controller? The information as below will help you to know more.

Because the ebike kit system will use1-5 bus cable as connection, so we can transfer some functional cables there:

That's the reason why AW electric controller has fewer cables compared with NC electric bike controller.

Maybe you will have questions, where can you put the ebike controller when you install it in the electric bicycle?

Here are some solutions for your option.

750W 1000W 1500W 12 mosfet ebike controller bag

12FB model

750W 1000W 1500W 12 mosfet high power

ebike motor controller bag (12FB)

Square wave ebike controller VS Sinewave ebike controller

| Square wave eBike controller | Sinewave eBike controller | |

| Advantage | easier to mtach with the whole ebike system (more simple, more reliable) | almost mute during the whole process |

| cheaper | generally speaking, linearity is better than square wave control | |

| consume less electricity when cruising | motor efficiency is higher under heavy loading and acceleration (the waveform fits more perfectly with the working principle for the motor) | |

| more obvious when accelerating | ||

| EABS braking effect is stronger | ||

| high ratio of voltage utilization ,and can run out of motor speed without weak magnetic field directly | ||

| Disadvantage | Bigger start-up vibration,for 0-5km/h | not as easy as square wave control when matching with the whole ebike system |

| more noise | higher cost, the price difference is big especially for high power ebike controller | |

| not smart enough, normally can't be adjusted after leaving the factory | consumes more power than square wave control, for the electric bike controller itself. | |

| The motor efficiency is low, when doing acceleration and heavy loading, etc. | The extreme speed is around 86%, and higher speeds need to be matched with the field weakening function. |

SPECIFICATION

| Product name | 12 mosfet ebike controller |

| Model | 48V 30A 35A-AW/Normal |

| Rated Voltage | DC24-72V |

| Rated current | 20A |

| Maximum current | 40A |

| Rated power | 480W-1440W |

| Maximum power | 2880W |

| Static power comsuption | <50mA |

| Under-voltage protection | it can be set according to customer requirements |

| Driving mode | Sinewave or Square wave for option |

| Waterproof | Basic protection of water washout IP64 |

| Electromagnetic compatibility(EMC) | Outgoing lines can be added with the jacketed ring for interference protection |

| Lights drive | Optional headlight control and instrument headlight indicator |

| Housing color | aluminum natural or black |

| Product certification | CE certification |

Usually, 12 mosfet controller is used to fit 750W 1000W 1500W standard electric bike hub motor.

The ebike controllers we provide use imitate torque control mode to help achieve a smooth start-up of the vehicle, the power-assist drive will be smooth and natural.

Electric power assist is with fast response and always consistent with the rider's pedal action to achieve the effect of the torque boost.

With multiple protection features such as stalled, over-current, over-temperature, over-voltage, under-voltage, speed, lack of phase and so on to protect the safety of vehicle electronic control systems and traffic.

There are motors with or without Hall, which fit all kinds of high and low speed motors.

There are two options of simulated sine wave or square wave controller.

NC model

12 mosfet ebike controller with normal SM connectors

(Motor connector is Julet 8 pin waterproof connector)

12 mosfet ebike controller with Julet waterproof connectors

Size information for the 12 mosfet ebike controller aluminum case:

Someone will have questions, why the AW model controller have fewer cables in the controller? The information as below will help you to know more.

Because the ebike kit system will use1-5 bus cable as connection, so we can transfer some functional cables there:

That's the reason why AW electric controller has fewer cables compared with NC electric bike controller.

Maybe you will have questions, where can you put the ebike controller when you install it in the electric bicycle?

Here are some solutions for your option.

750W 1000W 1500W 12 mosfet ebike controller bag

12FB model

750W 1000W 1500W 12 mosfet high power

ebike motor controller bag (12FB)

Square wave ebike controller VS Sinewave ebike controller

| Square wave eBike controller | Sinewave eBike controller | |

| Advantage | easier to mtach with the whole ebike system (more simple, more reliable) | almost mute during the whole process |

| cheaper | generally speaking, linearity is better than square wave control | |

| consume less electricity when cruising | motor efficiency is higher under heavy loading and acceleration (the waveform fits more perfectly with the working principle for the motor) | |

| more obvious when accelerating | ||

| EABS braking effect is stronger | ||

| high ratio of voltage utilization ,and can run out of motor speed without weak magnetic field directly | ||

| Disadvantage | Bigger start-up vibration,for 0-5km/h | not as easy as square wave control when matching with the whole ebike system |

| more noise | higher cost, the price difference is big especially for high power ebike controller | |

| not smart enough, normally can't be adjusted after leaving the factory | consumes more power than square wave control, for the electric bike controller itself. | |

| The motor efficiency is low, when doing acceleration and heavy loading, etc. | The extreme speed is around 86%, and higher speeds need to be matched with the field weakening function. |